Wireless sensor system for packaging company

35%

cost reduction

20%

energy efficiency boos

70%

less damaged packages

Challenge

Ensuring quality monitoring of environmental parameters in the packaging area.

Solution

Comprehensive wireless sensor system tailored to the specific needs of the packaging company.

Tech stack

.NET, Azure, React, BI, Big Data.

Client

Enterprise-scale Chinese company specializing in manufacturing printing rolls and aluminium laminates food product packaging. They hold a prominent position in the market and are renowned for their expertise in manufacturing printing rolls and aluminum laminates used in the food and consumer goods industry. With ownership of multiple factories, the client possesses a robust production capacity that enables them to meet the demands of their discerning customers. Committed to upholding the highest standards of quality and safety, they place great emphasis on maintaining a controlled production environment within their workshops.

Challenge

The customer faced a critical need to maintain strict control over their workshop environment to ensure compliance with food safety and hygiene standards. This required the implementation of a sensor-based system for tracking and managing crucial factors such as air temperature, gas concentration, humidity, and more.

To minimize defective packages, comprehensive monitoring of the entire product manufacturing and storage processes was essential. This could be achieved through a dedicated app, enabling responsible and supervisory personnel to oversee and control preset parameters.

During the software development phase, the following factors were prioritized:

- centralized control of parameters through a unified app;

- in-depth analysis of data and parameters to generate reports within specific time periods;

- forecasting of key indicators and capacity utilization based on the product type;

- cost optimization for electricity and efficient use of production resources;

- seamless integration of the software with other operating systems used within the company.

Got a similar software development project on your mind?

Estimate a precise timeframe for its implementation.

Team

1

Project manager

1

Business Analyst

1

Data Analyst

1

Architect

1

Team Lead

1

BI Engineer

6

Developers

2

Data engineers

Process

To tackle the challenges at hand, Modsen and the client embarked on a collaborative journey, following an Agile approach to development. The project encompassed the following stages:

1. Initiation

Clear goals, objectives, and requirements were defined, and establishing a shared vision and direction laid a solid foundation for successful collaboration. To ensure seamless implementation, experienced professionals, including a project manager, business analyst, and technical architect, were appointed. Effective communication channels were established for transparency and collaboration, with regular meetings and feedback sessions. Time and resource management were prioritized through realistic deadlines and suitable budget allocation. After a comprehensive analysis, the core tech stack was chosen, comprising .NET, Azure, and React, leveraging scalability and industry best practices. With all elements in place, the initiation stage set the project up for success, paving the way for subsequent stages to bring the wireless monitoring and control system to life and overcome the packaging company’s challenges.

2. Discovery

The initiation stage set the project in motion, and as the development process progressed, the project team delved into the discovery phase. This stage was dedicated to gaining a deep understanding of the organization’s existing processes, identifying areas for improvement, and exploring the feasibility of the IoT solution. Collaborating with stakeholders ensured that the development process aligned with their needs and goals. Feasibility studies evaluated the viability of integrating wireless sensors into packaging processes, considering technical, operational, and financial factors. A significant milestone was reached with the production of extensive documentation, capturing insights into existing processes, pain points, and areas for improvement. This detailed reference provided invaluable guidance throughout the development process, resulting in a design concept that aligned the technical solution with specific requirements.

3. Planning

After completing the discovery phase, Modsen embarked on creating a detailed project plan, carefully outlining the tasks, milestones, and deliverables that needed to be accomplished. The comprehensive plan served as a clear roadmap, allowing the team to effectively manage resources, timelines, and dependencies throughout the development journey. A vital aspect of the planning stage was defining the architecture and infrastructure required for the wireless sensor system. Our experts designed a robust and scalable architecture that would support the desired functionalities and meet the requirements. By carefully considering factors such as data flow, integration points, and scalability, Modsen ensured a solid development base. Through close collaboration with the client and leveraging insights gained during the discovery phase, the team prioritized the features that would add the most value and effectively address the company’s pain points. Testing strategies and quality assurance processes were defined to guarantee the reliability and stability of the solution. By implementing thorough testing methodologies, the team aimed to identify and address potential issues or bugs early in the development process. Embracing Agile principles, Modsen broke the project into manageable sprints and iterations. This approach allowed for regular feedback, continuous improvement, and the ability to adapt to changing requirements while fostering collaboration, transparency, and flexibility throughout the development process.

4. Development

Having completed the planning journey, the project embarked on the path of development, where the envisioned solution began to materialize. The dedicated team exerted great effort to transform the client’s requirements into a tangible system, utilizing the chosen tech stack.

Building a robust backend infrastructure:

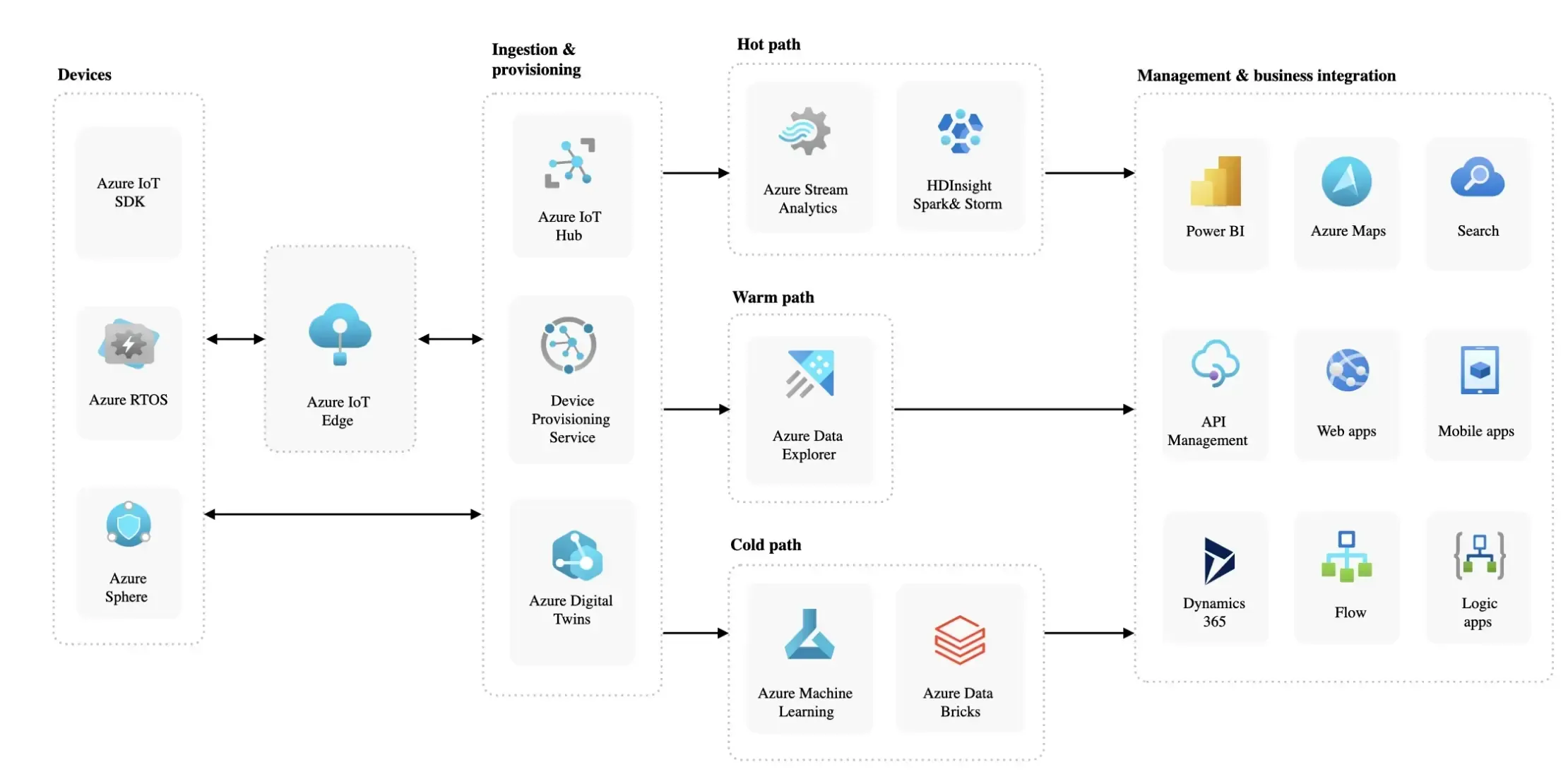

Drawing upon the selected technology, Modsen dedicated their efforts to constructing a robust backend infrastructure that enabled smooth data collection and analysis. By harnessing the power of .NET the team laid a strong foundation for efficient and reliable software development, enabling the creation of a versatile and scalable application. In addition, Modsen leveraged the capabilities of Azure to establish a comprehensive and secure infrastructure for data management and storage. The cloud-based services provided by Azure offered scalable and flexible solutions, ensuring smooth data collection, storage, and analysis from sensors. With the utilization of Azure IoT, the handling of sensor data was streamlined, allowing for real-time insights and actionable intelligence.

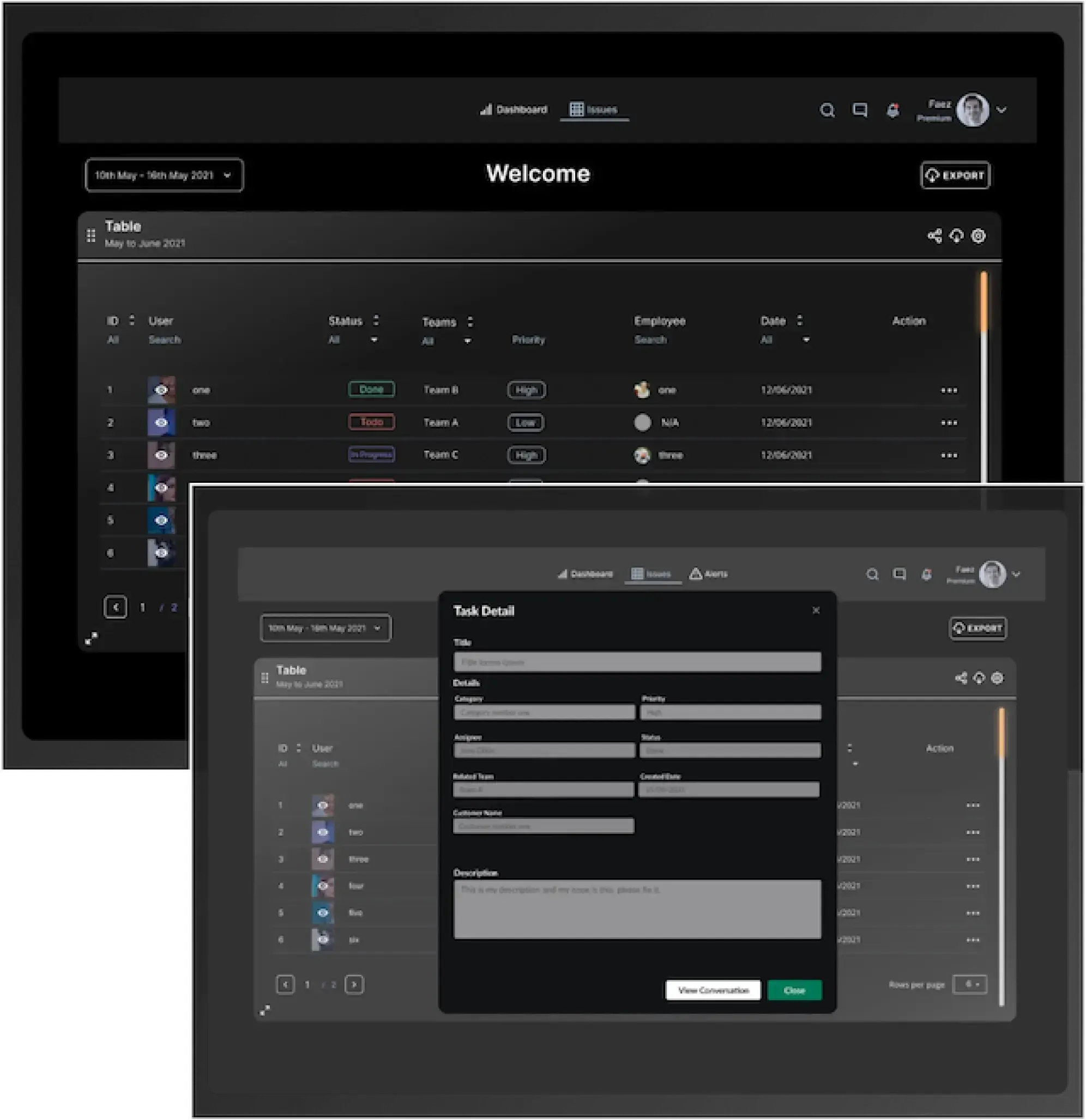

Dynamic user interface with React:

Through the integration of React, the team brought forth a dynamic and interactive user interface for the wireless sensor system. React’s powerful rendering capabilities and component-driven approach created a dynamic and immersive experience. The result? An interface that’s intuitive, user-friendly, and supercharged with productivity for the packaging company’s personnel.

Data-driven insights with BI:

The integration of BI (Business Intelligence) capabilities empowered the client with valuable data-driven insights. Modsen implemented BI tools and techniques to extract, transform, and analyze sensor data, providing meaningful reports, visualizations, and dashboards. By leveraging these valuable insights, the client gained the ability to make informed decisions, optimize processes, and identify areas for improvement.

Efficient handling of Big Data:

Harnessing the power of Big Data, the solution efficiently handled and processed large volumes of sensor data. This capability allowed for the identification of valuable patterns, trends, and anomalies that might have otherwise been overlooked. With advanced analytics and machine learning algorithms, the system provided deeper insights and predictive capabilities for the packaging company.

Solution Architecture

Integration with the packaging production environment:

A pivotal step in the development process was the integration of the wireless sensors with the packaging production environment. With precision and care, the team established connections between the sensors and the machinery, enabling seamless data transmission. This integration allowed for real-time monitoring of critical parameters such as air temperature, gas concentration, and humidity.

Rigorous testing and compliance:

To ensure reliable and stable performance, comprehensive testing methodologies were implemented. Modsen conducted rigorous unit testing, integration testing, and system testing to identify and resolve any bugs or issues. In pursuit of compliance with industry standards and regulations, the solution underwent thorough third-party audits. The team subjected it to a meticulous review, evaluating its adherence to industry best practices, safety standards, and data privacy regulations. Additionally, relevant certifications were obtained to validate its compliance and provide stakeholders with assurance. These meticulous development efforts paved the way for a powerful and effective sensor-based monitoring and control system, poised to revolutionize the client’s packaging operations.

5. Closing Highlights

In the final phase, Modsen closely collaborated with the client to validate the solution, provide training and documentation, and prepare for production deployment. Comprehensive deliverables were compiled, including project artifacts and a user guide. A thorough assessment was carried out to evaluate the achieved results and identify potential areas for future improvement. This phase marked the successful conclusion of the collaboration, delivering an approved solution ready for deployment in the client’s packaging operations.

Solution

Modsen developed a comprehensive wireless sensor system tailored to the specific needs of the packaging company. It aimed to ensure stringent control of the manufacturing environment quality in the workshops, monitoring crucial parameters such as air temperature, gas concentration, and humidity. The key functionality of the solution included:

Real-time Monitoring:

The system enabled real-time monitoring of various parameters within the production environment. The sensors collected data continuously and transmitted it to a central application, providing instant visibility into the conditions and allowing for prompt responses to any deviations or issues.

Centralized App:

A user-friendly and intuitive application was developed to consolidate and present the collected data from the sensors. The application could be accessed via desktop or mobile devices, enabling responsible and supervisory personnel to monitor and control the manufacturing environment from anywhere, at any time.

Parameter Analysis and Reports:

The solution provided an in-depth analysis of the collected sensor data, allowing for comprehensive insights into the production environment. The application compiled reports over a certain period, highlighting trends, patterns, and anomalies in the monitored parameters. This facilitated data-driven decision-making and proactive management of the operational procedures.

Capacity Utilization Forecasting:

Leveraging the collected data and advanced analytics capabilities, the system offered the ability to forecast capacity utilization based on the complexity of the manufactured product. Online notifications and detailed reports provided users with valuable insights, empowering them to optimize resource allocation and maximize production efficiency.

Resource Optimization:

The wireless sensor solution supported cost optimization for electricity and the effective utilization of resources involved in the production process. By grouping settings under certain conditions and providing recommendations on adjustments and changes, it aimed to optimize resource usage and minimize waste.

Agile Integration and Scalability:

The developed application was designed with an agile approach, allowing for the seamless integration of additional features, processes, and third-party operating systems required for high-quality product manufacturing. This ensured scalability and adaptability as the company’s needs evolved. The solution demonstrated a holistic approach to monitoring and controlling the manufacturing environment, enabling the packaging company to adhere to strict safety and hygiene standards. By providing real-time data, analysis, forecasting, and resource optimization capabilities, the wireless sensor system facilitated improved quality control, reduced defective packages, enhanced energy resource efficiency, and streamlined workflow, ensuring the packaging company’s ability to deliver safe and high-quality products to its customers.

Result

With the completion of the project, the client’s initial expectations for the solution have been put into practice and are currently undergoing preliminary analysis. Having utilized the system for a period of time, the client has conducted several assessments to evaluate its performance. While a comprehensive understanding of the final results will be available at the end of the year, the initial analyses conducted thus far provide promising insights. Here is a glimpse into what the client has observed:

- Reduction in Defective Packages: The goal of achieving a significant decrease of 50% to 70% in the number of defective packages is showing promising signs of being met. The real-time monitoring and control capabilities of the wireless sensor system have played a pivotal role in identifying and rectifying issues, leading to improvements in product quality.

- Cost Savings: Optimizing resource utilization and enhancing production processes were expected to result in cost savings of 25% to 35%. The interim analysis reveals promising indications that the solution delivers these anticipated savings. Identifying inefficiencies and minimizing waste, it is helping the client optimize their resource allocation and achieve tangible financial benefits.

- Energy Resource Efficiency: Seeking to achieve energy savings of up to 20%, the company implemented proactive monitoring and energy optimization strategies with the help of wireless sensors. Encouragingly, initial findings suggest that the solution is making substantial strides in enhancing energy efficiency, bolstering the client’s efforts to reduce their energy consumption.

- Improved Monitoring and Adjustments: The projected productivity improvements of 50% to 70% by streamlining processes and optimizing resource allocation are being realized through the sensor-based solution. The system’s real-time data analysis and reporting capabilities are exceeding expectations by offering actionable insights and enabling data-driven decision-making.

- These promising results validate the client’s decision to invest in advanced sensing technology and provide them with increased confidence in the system’s potential to drive positive impacts across their operations. With regular utilization of the solution, the client can continue to reap the benefits and achieve their desired outcomes.

50%-70%

Defective Packages Reduction23%-35%

Cost Savings20%

Energy Efficiency Increase50-70%

Improved Monitoring and AdjustmentsLet's calculate the accurate cost and resources required for your project